Discover all our Business Sectors

A strong presence since 1955, the press tools and punching units SUPRA are world famous. Our activity, present in all sectors of industry, construction, transport, energy, publishing, engineering, education, state services and social organizations, is based on the satisfaction and trust of more than 2000 customers.

Discover all our Business Sectors

SUPRA Units

Definition

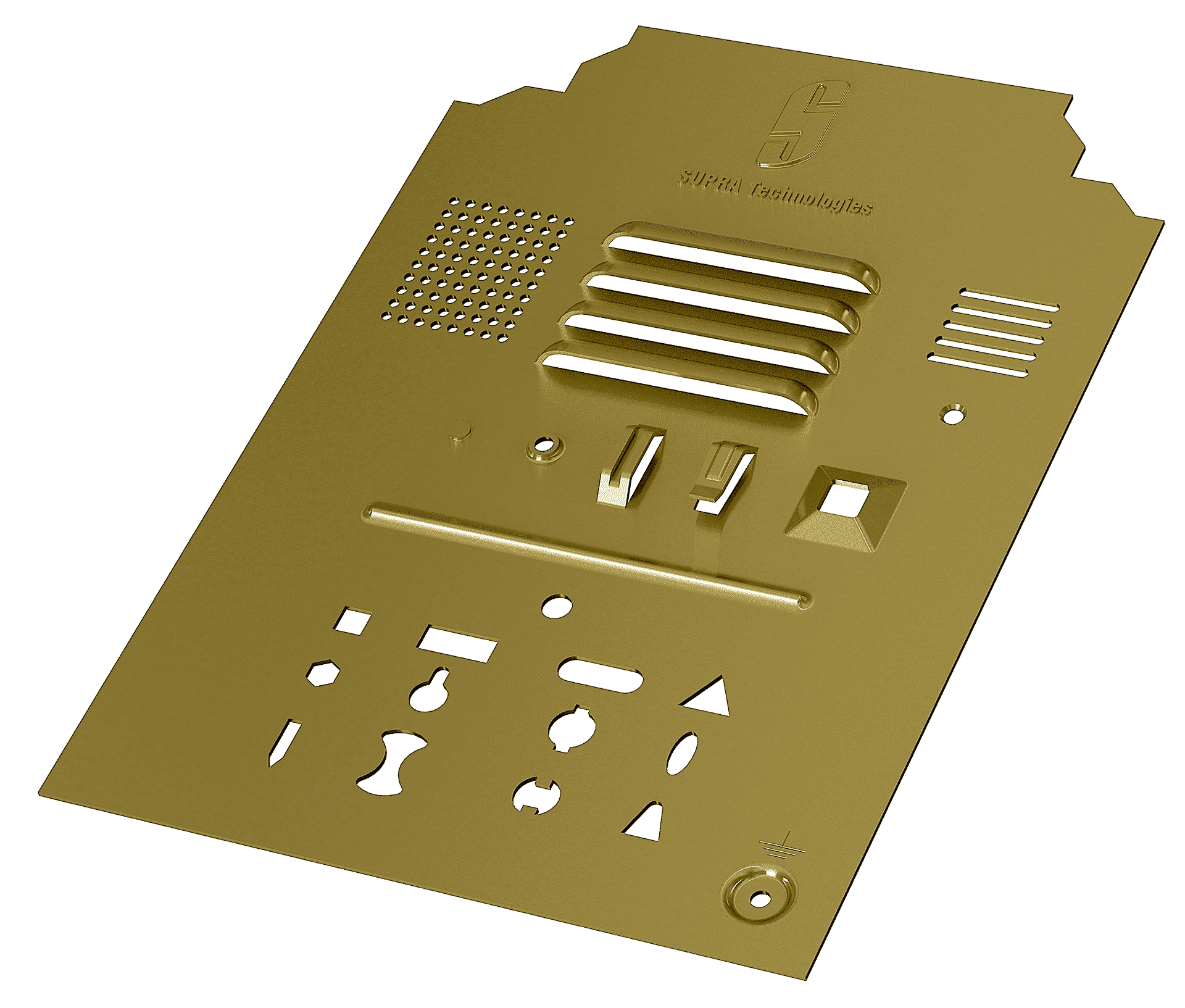

Punching units are tools capable of performing unitary punching, notching or cutting-off work in sheet metal, profiles or tubes.

SUPRA units can be used on presses, press brakes of any type or in assembly integrating pneumatic, hydraulic, oleopneumatic or electric energy.

The SUPRA unit is the economical and rational solution adapted to all your manufacturing problems for medium and large series and repetitive parts.

Description

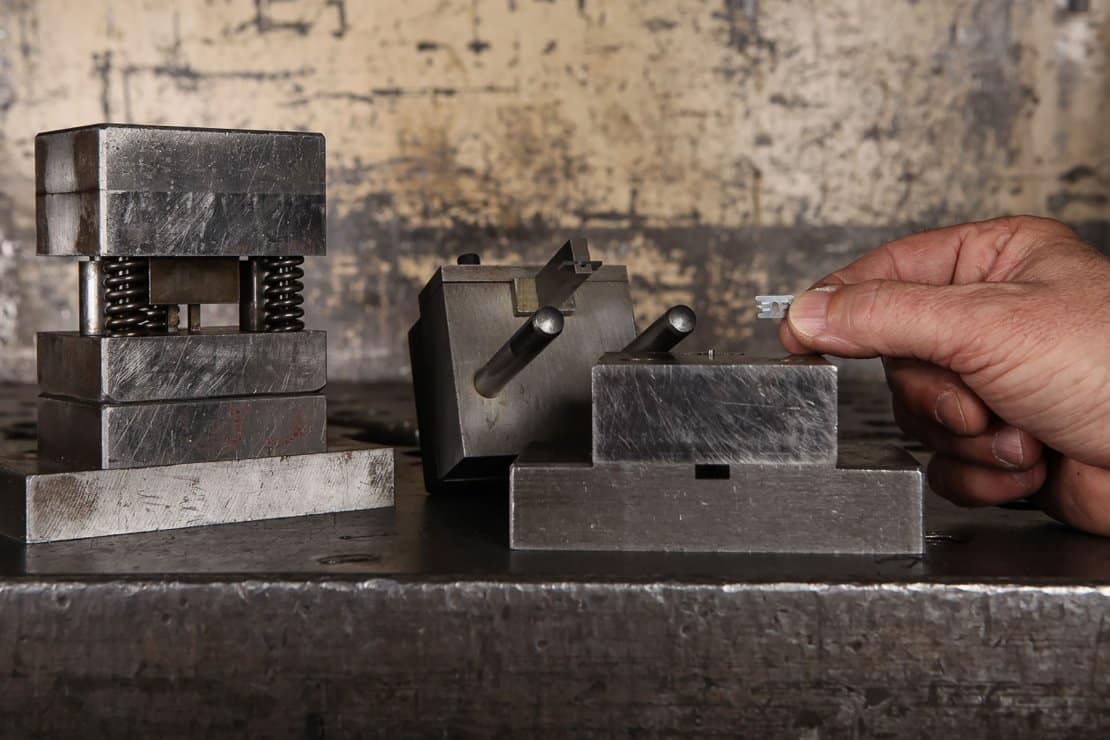

The SUPRA units consist of a body whose function is to provide the geometrical link between the punch and die. The punch holder is supplemented in the punching and notching units by a stripping assembly.

Setting up

The SUPRA units, thanks to their universality and their autonomous mobility, do not need to be attached to the upper part of the unit (except the units type PAL, PAEL and TT). Their positioning is ensured by a Ø8 pin located under the base plate in the punching axe.

Functioning

As the SUPRA unit is attached to the press table, the adjustment of the press ram closure or the adjustment of the bottom dead center (HOF) is of high importance. This rating is given for each unit. The unit is thus ready for use. The nose of the press come sinto contact with the striking plate. At the unit level, the sequence of operations is as follows :

- Descent of the press

- Bending of the ascent springs

- Contact of the stripper on the sheet metal

- Bending of the stripping springs

- Punching

- HOF reached

- Press pick-up

- Stripping the punch

- Raising the set

The punch is not integral with the slide, the body of the unit is not subjected to any mechanical stress.

Recommendation and maintenance

Set your press low dead point (HOF). This must in no case be less than the HOF indicated by the unit concerned or on the tool identification plate.

- The HOF must be checked periodically in fonction of the cadence and time.

- Check the condition of your punches and dies regularly (no wear and defects).

- Punches and dies must be sharpened regularly. Grinding 1/10 of the cutting faces, without waiting for a defect to appear, increases the longevity of the tool.

- After sharpening, the elements must be demagnetized.

- Carefully check the clearances between punches and dies. The clearances are adapted to the thickness and grade of the material.

- Regularly check that all components are securely fastened.

- Keep the tool clean.

- Periodically grease all moving parts of the tool.

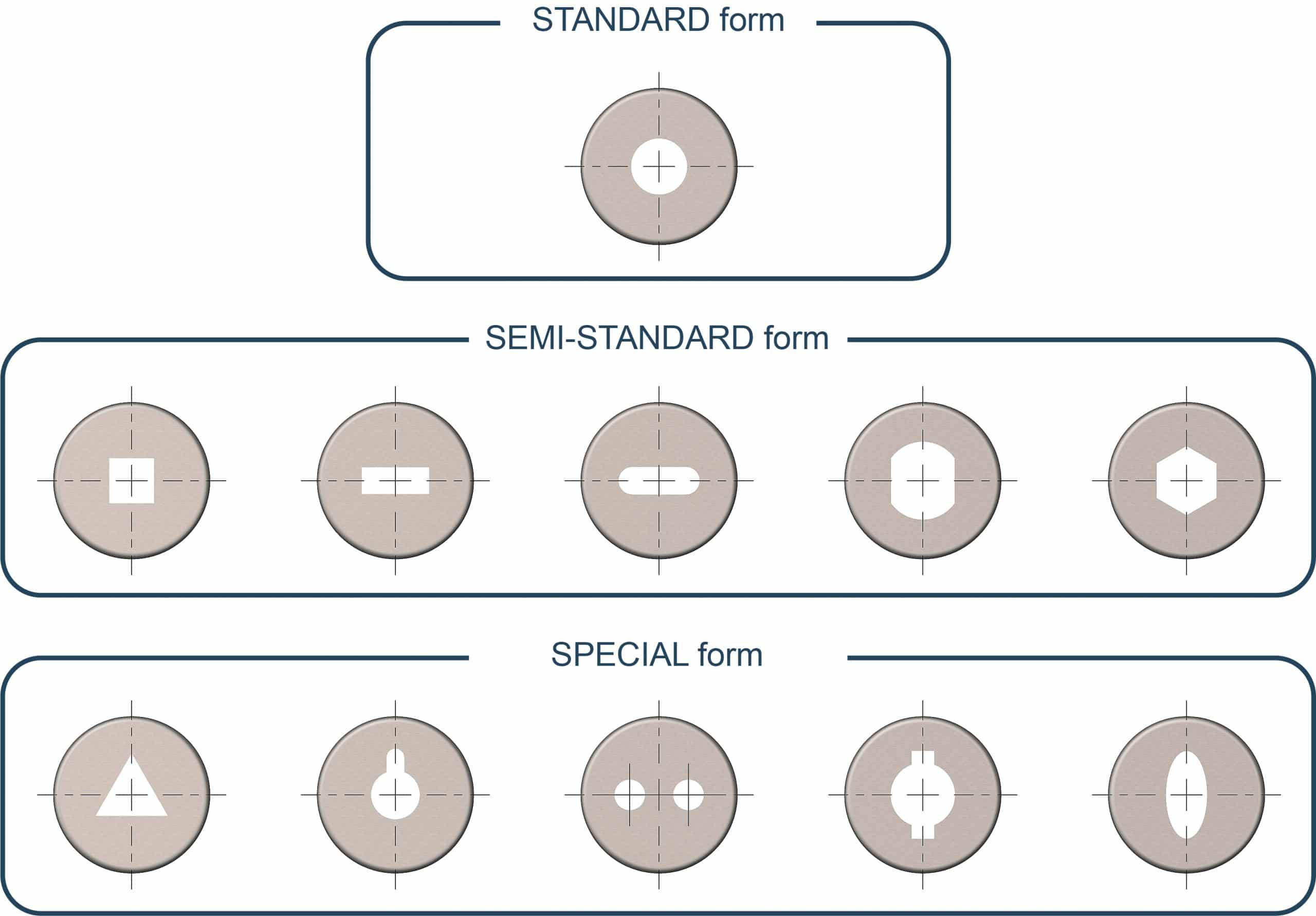

Punching forms

The punches and dies (1/2 standard and special ones) must fit within the maximum punching Ø of the corresponding unit.

The SUPRA units are press tools that are very easy to use and operate, capable to obtain a wide variety of punches shapes, but also to carry out punching, creasing, embossing, marking, bending and stamping operations.

Indoor & Outdoor space

Very present in interior / exterior design, SUPRA Technologies operates in the manufacture of press tools for all sheet metal parts, tubes and profiles for equipment related to individual and industrial housing. Our activity is the manufacture of street furniture, metal frames, lighting and interior furniture, whether industrial, collective or private.

In your dialy life, a very large number of parts made from sheet metal, tubes or profiles surround you. Your garden furniture chair, your radiators, your door handles, your letterbox and many others are made from press tools.

Luxury

Punching units are not reserved for heavy duty work. They are perfectly adapted to operations demanding special care and requirements. SUPRA Technologies operates in the leather goods and fountain pen manufacturing sectors, but also in the medical sector where the levels of constraint and requirements are very high.

Transport

The transportation sector is very large. SUPRA Technologies is strongly involved in the manufacture of parts for automotive, railway, public transport, motor sports and all peripherals related to these activities. A large number of accessories come from SUPRA Technologies tools such as roof bars, light or heavy truck trailers.

Metal construction

The production of industrial or engineering metal structures requires the use of press tools. These tools can be simple or complex. This work is generally carried out on medium and thick plates or profiles. For many years, SUPRA Technologies has been designing and manufacturing tools for the production of frames and shelving for logistics.

Agriculture

Strongly present in the agricultural world, SUPRA Technologies is involved both in the manufacture of equipment and accessoires for vehicles and in all developments for animal breeding. It is a know-how in the production of highly technical parts equipping the most modern vehicles, but also an involvement in vineyards and vegetabl cultivation.

Leisure

Camping holidays, DIY (do it yourself), sports, music, horse riding, hiking, art and shows, SUPRA Technologies marks its presence in all these activities.

Aerospace

SUPRA Technologies participates in the manufacture and constitution of tool sets allowing the realization of technical parts such as piping and instrumentation in the aviation and defence sectors.

Energy

A large number of sheet metal workpieces are input elements in the production of electrical, solar, photovoltaic and « water » energy. The presence of SUPRA Techologies participates in the development of sustainable and renewable energies.