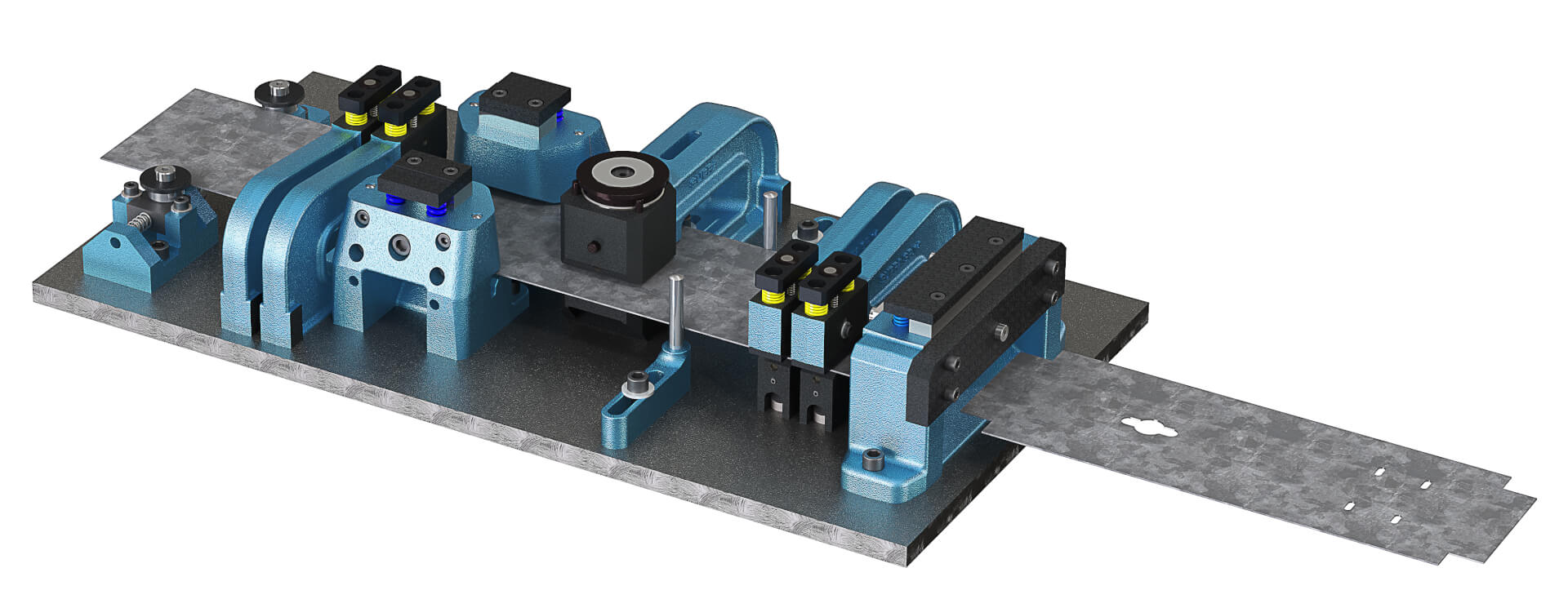

Implementation plate

The SUPRA units are universal among them. These can be used combined or individually.

Depending on the diversity or repeatability of your parts, SUPRA units meet the most diverse repuirements.

When you combine several units on an implementation plate, you can manufacture series of parts with different punching, notching and notching patterns according to your needs. Avoiding multiplication of tools, you get a modular and economical solution.

Assembling on an implementation plate, by combining several SUPRA units, you have the possibility to build and obtain almost infinite shaped cuts-outs of your parts. Equipped with a whole range of accessories, your work can be carried out from reel tape or cut blanks. These accessories will guarantee the positioning and holding of the material.

Our sales and design office teams study all your requests and offer you a personalised solution adapted to your needs while taking into account your production requirements.

Combination of SUPRA units on implementation plate

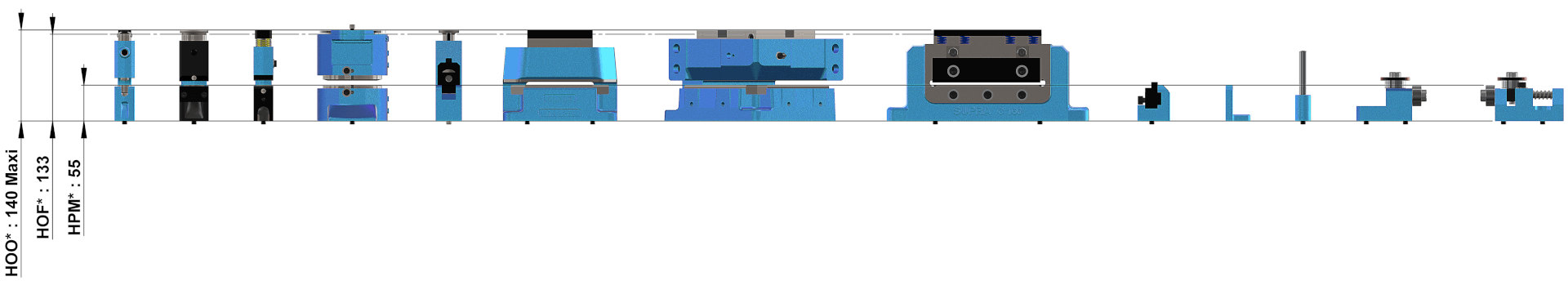

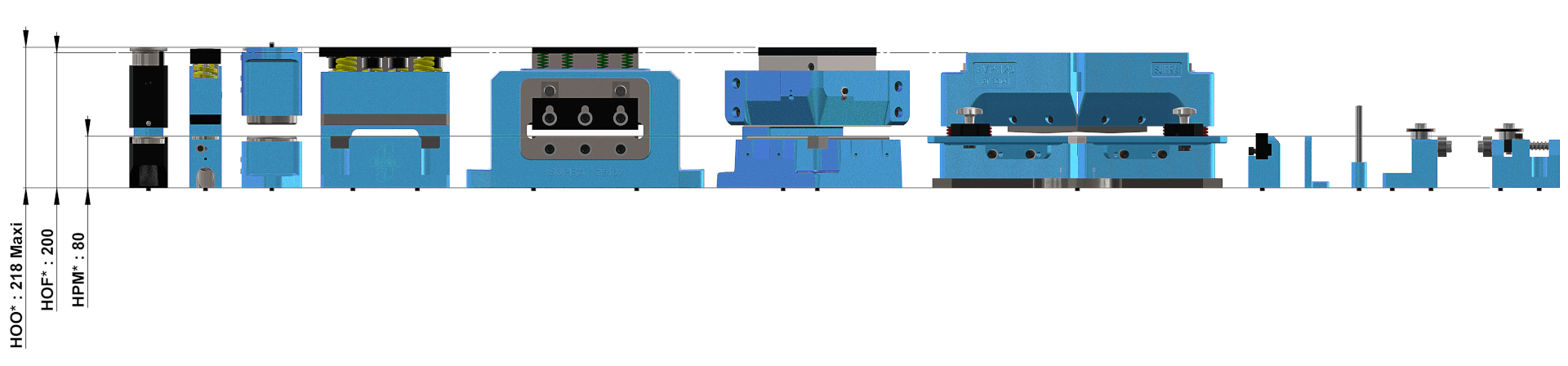

The combinations of SUPRA units on implementation plates are distinguished by the thickness of the material to be processed.

For work on all materials up to 4mm thick, the series CLAP, PA, SPR, PAL, PAH, G, E & EC and C, with the corresponding accessories, you can obtain an infinite number of combinations. The open tool height (HOO) or press passage, the closed tool height (HOF) as well as the distance of the sheet metal from the table (Die Plate Height HPM) is common.

Combination of SUPRA units for working sheets up to maximum 4 mm thick

For work on all materials up to 10 mm thick, the series PAE, SPAE, PAEL, GE, EE & EEC, CE and EVP with the corresponding accessories, you can obtain an infinite number of combinations. The open tool height (HOO) or press passage, the closed tool height (HOF) as well as the distance of the sheet metal from the table (Die Plate Height HPM) is common.

Combination of SUPRA units for working sheets up to maximum 10 mm thick