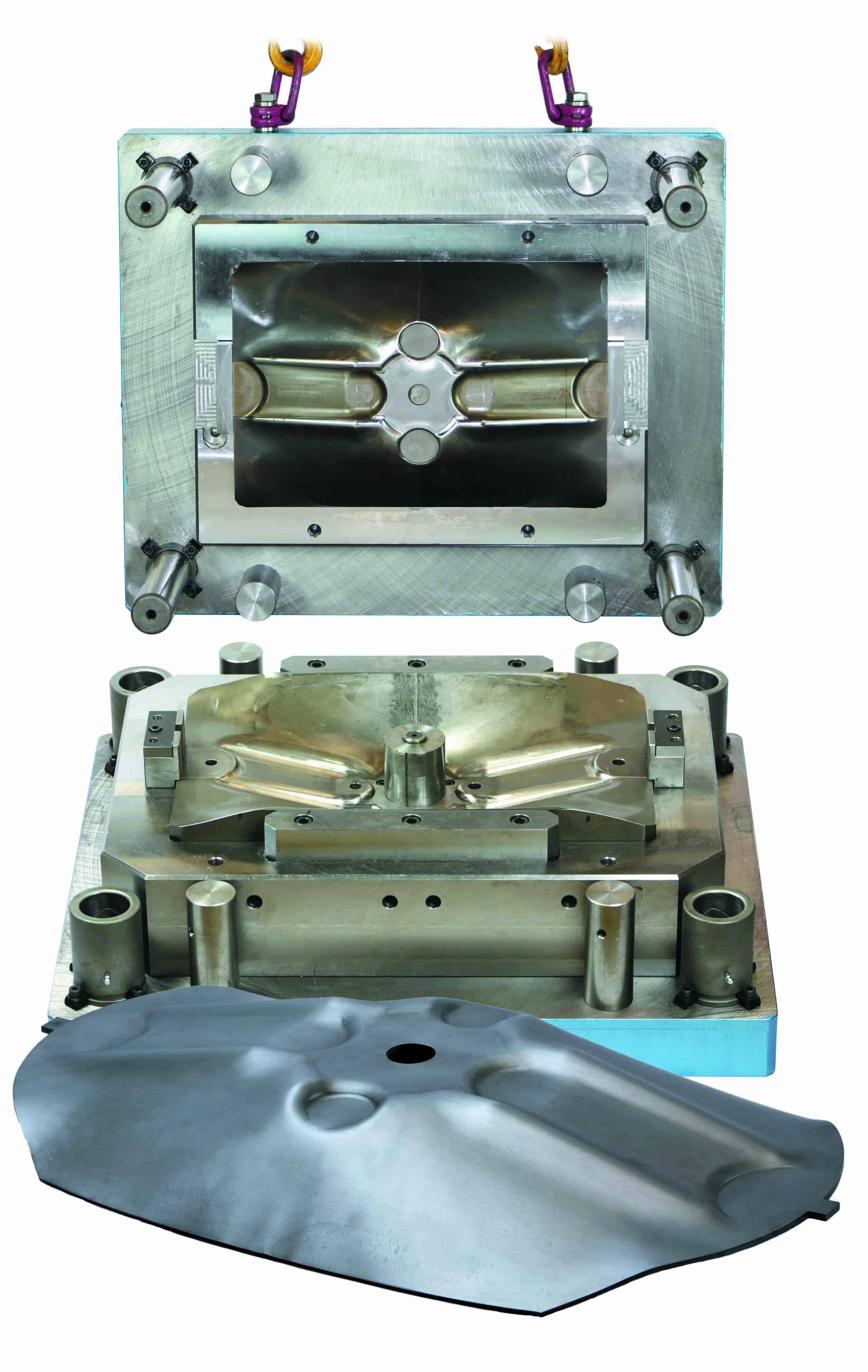

Stamping tools

SUPRA Technologies, specialized in press tooling, designs and manufactures stamping tools. Equipped with SOLIDWORKS and LOGOPRESS software, SUPRA Technologies teams study all your requests and needs in press tools.

Stamping tools

Stamping is a mechanical forming process for non-developable parts. The plastic deformation of a metal surface is driven by a punch in a die to elongate and shrink the material. The transformation of the surface is carried out by molecular displacement.

The stamping operation produced in a single operation is called a shallow stamping. When it requires several drawing passes, it is called deep-stamping.

Stamping causes a permanent deformation of the metal and requires very important efforts modifying deeply the characteristics of the material. As a result, the material’s tensile strength and yield strength are increased while its percent elongation is reduced. The metal is getting hard. This work hardening limit is decisive for the number of deep-stamping passe. It may be necessary to anneal between passes.

A part of obtained by stamping from pre-cut blanks or from strip. Working from blanks applies to unitary work, small series. Also used for large series, it is reserved for large formats. Tape work is carried out using follow-on or progressive tools. It is reserved for the production of parts in large series.

Stamping tools can combine operations such as punching and routing. They become compound tools.

The parts generated by these tools can be retrieved at their ends opposite to the material inlet, or underneath, commonly referred to as the « pass through ».

Knockouts or waste from punching and cutting operations are removed from underneath. A scrap outlet is to be taken into account either through the evacuation hole provided through the press table or by placing cleats between the lower block of the tool and the press table.