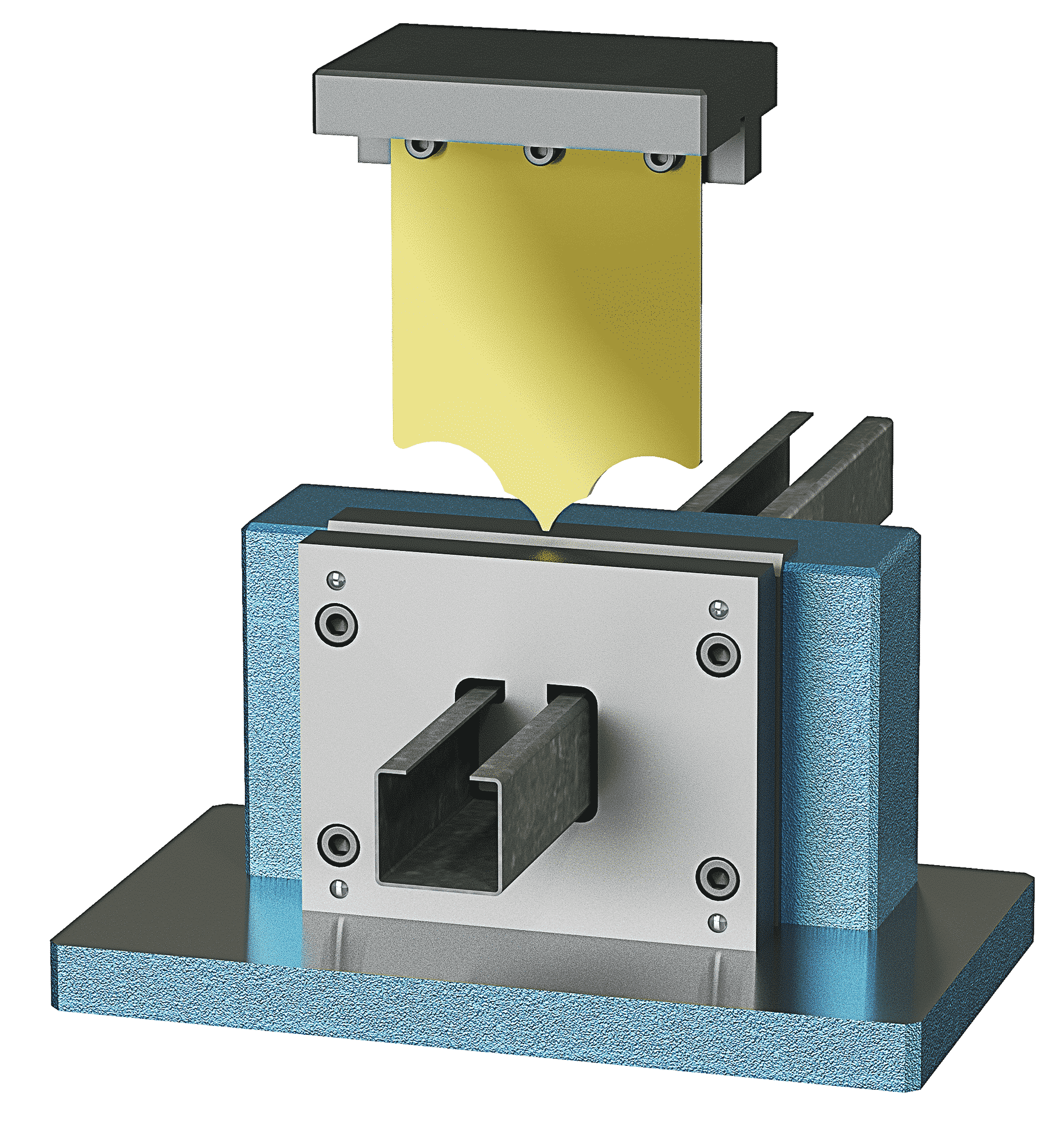

Profile cutting tool

The profile cutting tools allow the shearing or cutting off of all types of profiles.

Based on its experience, SUPRA Technologies studies the most suitable way to cut your profiles.

Profile cutting tool

The profile cutting tools are distinguished by the method of execution with or without drop. They appear indifferently under any type of press. SUPRA Technologies remains attentive to your needs and is able to offer you turnkey solutions.

Shearing is a no-loss cut. The advantage is no loss of material. The disadvantages are a lower quality end cut and the misalignment of the cut part at the tool outlet. This is retrieved in a different vertical plane from the tool input which is to be taken into account on automated lines. As a rule, the no-loss cutting process is reserved for use by manually feeding the profile to be cut. A fixed stop outside the tool marks the distance at which the profile will be cut.

Drop-cutting is a cutting-off operation. The major disadvantage of this process is the loss of part of the profile corresponding to the thickness of the blade it has cut. On the other hand, the cut will be clean and regular with faces rigorously parallel to the cutting plane and minimal burrs. Another advantage at tool exit is that the cut profile remains in the same axis as at entry, making it easier to manage on automatic lines. This process, more suitable for integration in automatic means, can be used in 2 ways : cutting the profile at standstill or cutting on the fly.

Cutting at standstill, i.e.the cutting tool is fixed under the press. The profile is fed by an automatic feed system. It manages the pitch or the length of the profile to be cut.

Cutting on the fly is a tool that integrates its source of effort. This assembly mounted on a mobile structure allows cutting without interrupting the profile feed. This is completely automatic and is fully managed by the production line. It is an ideal solution that integrates perfectly on profiling lines.