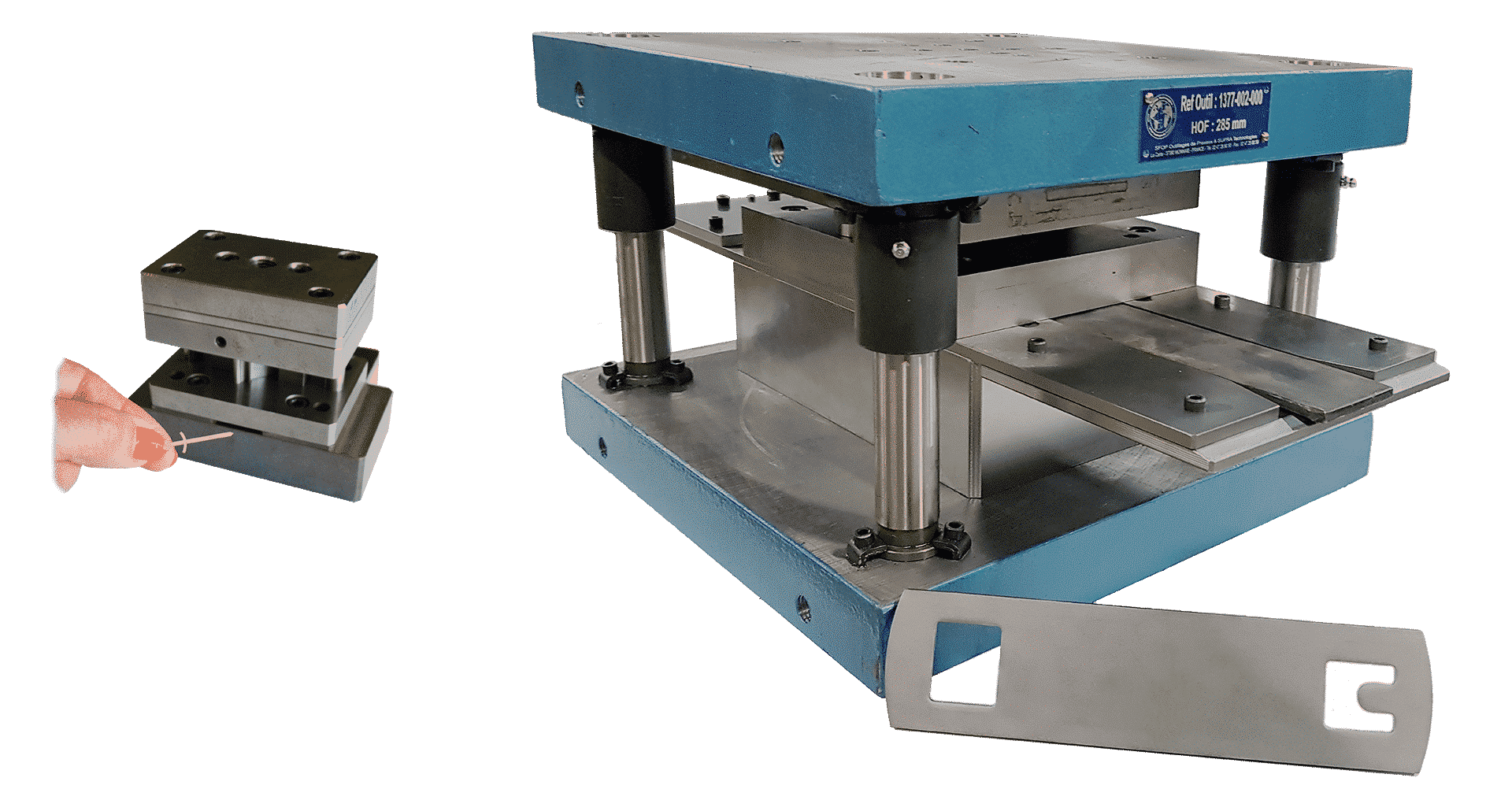

Punching tool with counter plate

SUPRA Technologies designs and manufactures punching tools with counter plates. These are fixed stripper tools.

These are an economical solution suitable for small, medium and large series and allow to carry out punching and cutting operations.

With its experience, SUPRA Techologies has acquired know-how in the manufacture of tools allowing the manufacture of parts of any material from 5/100 thickness.

Outil parisien ou à contre-plaque

Embedded tools, more often called punching tools with counter plate, are press tools with fixed stripper. The punches are permanently submerged or guided in the stripper.

Therefore, the use of a column guided tool step is not necessary under the following conditions : punching or cutting are carried out on thin material, because the clearance between punch and die is very low or that your press has no geometric defect at the level of the slide.

The use of a column guided tool step is justified by the work of medium and thick sheets or that there is a possible defect in your press.

The tools, integrated in a column guided tool step, can be made autonomous. This means, it is not necessary to have the mechanical connection with the press slide. The opening of the tool is actuated, in this case, by wire springs or gas springs. This solution saves time in setting up the tool in the press.

The operations performed on this type of tool are limited to the punching and trimming functions. They can be combined in several stages, thus becoming progressive or follow-up operation.

The stripper being integral with the matrix, the passage of the sheet is limited to the dimensions of the latter. No tape movement can be performed. Therefore, all operations involving the deformation of the sheet are prohibited. This architecture makes it possible to obtain very low press runs, hence a production with high production rates.

The use of the punching tool with counter plate is reserved for the use of material supplied in strips. The raw material supply in this type of tool can only be performed manually. The tool incorporates mechanical devices to mark time, by mechanical stops called « gearers » or pitch knives.

The evacuation of the parts generated by the tool can be recovered at its end opposite to the material inlet, or below, commonly called « the passage through ».

The waste due to the punching operations are evacuated from below. A fall outlet must be taken into account either by the evacuation hole provided through the press table, or by the installations of cleats between the lower block of the tool and the press table.